Sr. UX designer - Propriety enterprise apps

Sr. UX designer - Propriety enterprise apps

CASE STUDY

CASE STUDY

CASE STUDY

Walmart technician experience app

Walmart technician experience app

Walmart technician experience app

I led the process to create a new app for Walmart technicians to replace the outdated legacy system. Leveraged AI to prioritize work orders, simplify workflows, and reduce the reliance on multiple tools—ultimately boosting efficiency and reducing technician turnover.

Role

Sr. UX designer

Domain

Propriety enterprise apps

Consulted

Engineering, product, business partners, UX research, copywriters and facility operations

Role

Sr. UX designer

Domain

Propriety enterprise apps

Consulted

Engineering, product, business partners, UX research, copywriters and facility operations

Our users

Walmart technicians are responsible for maintaining and repairing equipment in Walmart stores. Their work spans across various areas like facilities maintenance, refrigeration, HVAC (heating, ventilation, and air conditioning), and sometimes automation systems. They handle tasks like fixing broken equipment, ensuring systems like refrigerators are functioning, and performing routine maintenance to prevent issues. Technicians work across multiple locations and play a key role in keeping operations running smoothly.

Walmart technicians

Our users

Walmart technicians

Walmart technicians are responsible for maintaining and repairing equipment in Walmart stores. Their work spans across various areas like facilities maintenance, refrigeration, HVAC (heating, ventilation, and air conditioning), and sometimes automation systems. They handle tasks like fixing broken equipment, ensuring systems like refrigerators are functioning, and performing routine maintenance to prevent issues. Technicians work across multiple locations and play a key role in keeping operations running smoothly.

The problem

Walmart technicians currently face significant challenges with the tools they use, leading to a high turnover rate of 70%. The primary app, Field FM, suffers from latency issues, uses outdated legacy software that is difficult to update, and lacks the ability to integrate new features easily.

In addition, work orders often get lost, and technicians struggle to find relevant information, as evidenced by quotes from the field. This increases onboarding time and causes delays in managing work orders. Technicians are also required to use multiple apps—such as Zeus for ordering parts and ME@campus for tracking their time—further complicating their workflow.

The problem

“I didn’t know what I was looking at. It takes a good month to get use to this (Field FM app).”

-Ron, GM Technician

“I didn’t know what I was looking at. It takes a good month to get use to this (Field FM app).”

-Ron, GM Technician

“I didn’t know what I was looking at. It takes a good month to get use to this (Field FM app).”

-Ron, GM Technician

“I get worried about aging work orders. Sometimes they get lost and you don’t have them available.”

-Kett, Refrigeration Technician

“I get worried about aging work orders. Sometimes they get lost and you don’t have them available.”

-Kett, Refrigeration Technician

“I get worried about aging work orders. Sometimes they get lost and you don’t have them available.”

-Kett, Refrigeration Technician

The process

The process

Discovery

Understanding users

User feedback on legacy app

Opportunity

User journey map

Design

Site map

User research

Qualitative - moderated user testing

Final design

Prototype

Engineering hand off

Accessibility annotations

What's next

How are we measuring success?

Enhancements

Discovery

Understanding users

User feedback on legacy app

Opportunity

User journey map

Design

Site map

User research

Qualitative - moderated user testing

Final design

Prototype

Engineering hand off

Accessibility annotations

What's next

How are we measuring success?

Enhancements

The process

Opportunity

Improve Information

hierarchy

Improving the organization of details within each work order to minimize onboarding time, help technicians get aligned faster, and prevent orders from being overlooked.

Reduce turnover

Provide a more intuitive, efficient tool that reduces frustration and errors, ultimately improving job satisfaction and lowering the 70% technician turnover rate.

Increase efficiency

Improving the organization of details within each work order to minimize onboarding time, help technicians get aligned faster, and prevent orders from being overlooked.

Optimize

performance

Optimize performance

Address latency issues by migrating from legacy software to a modern, easily upgradable system, ensuring faster response times and the ability to implement new features without delay.

Consolidate tools

Combine multiple tools (Field FM, Zeus, navigation, timeclock) into a single app to streamline workflows and reduce the complexity of managing tasks across different platforms.

Opportunity

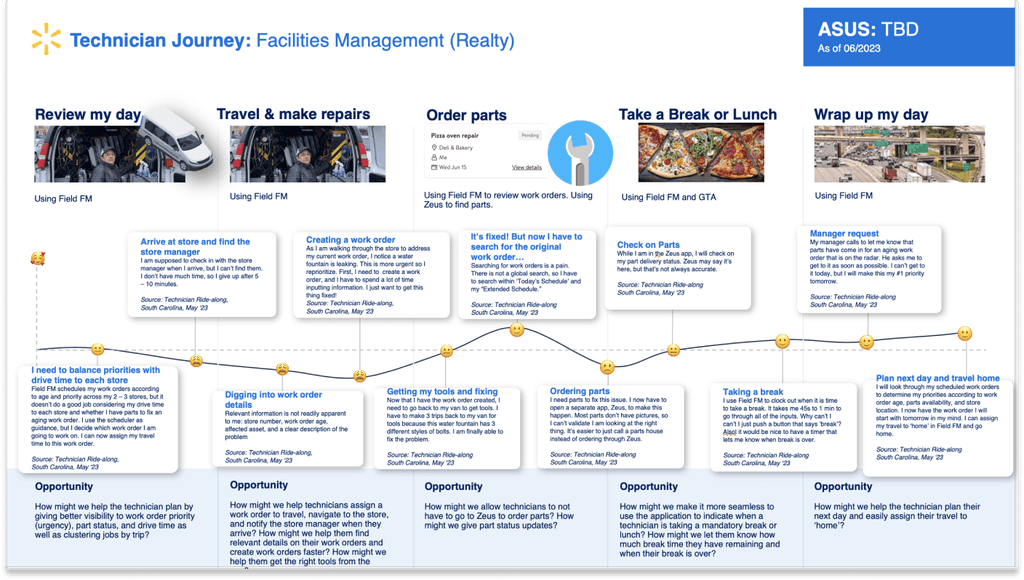

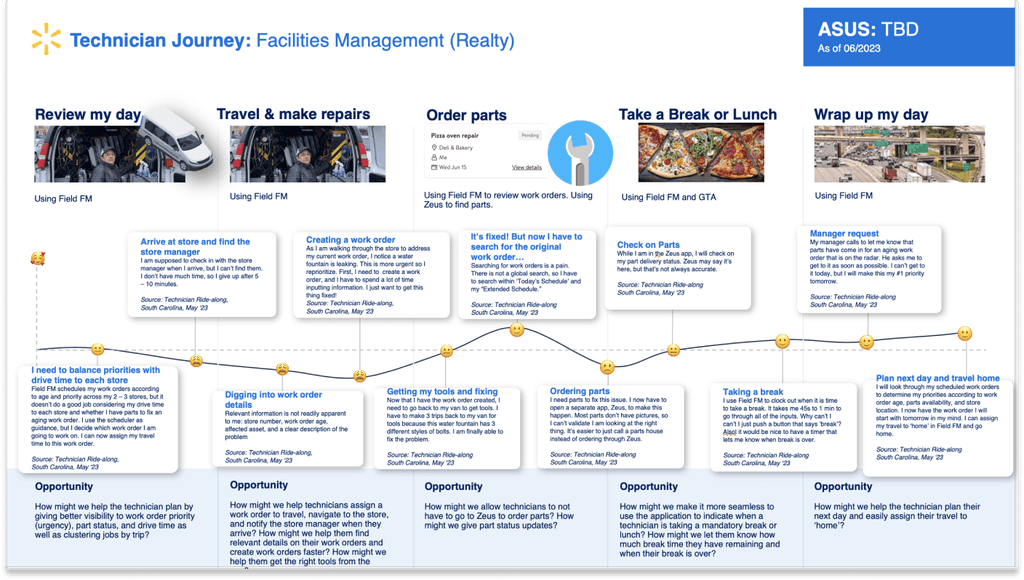

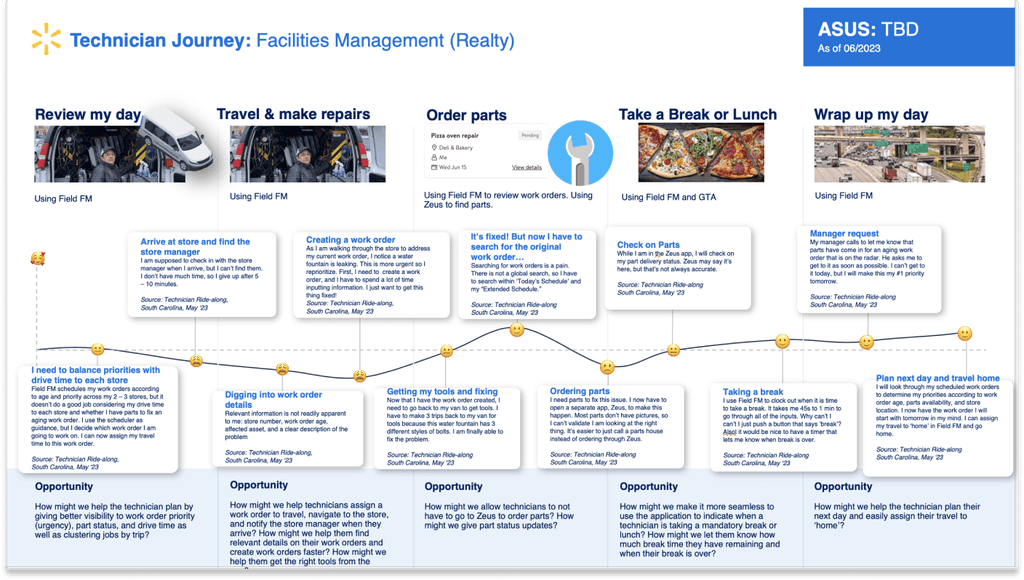

User journey

User journey

Understanding the Technician Experience

We conducted technician interviews to capture their pain points and positive experiences throughout their day. These insights allowed us to create a journey map that served as a valuable tool for feature ideation, facilitating discussions with the business, and building empathy for the challenges technicians face.

Understanding the Technician Experience

We conducted technician interviews to capture their pain points and positive experiences throughout their day. These insights allowed us to create a journey map that served as a valuable tool for feature ideation, facilitating discussions with the business, and building empathy for the challenges technicians face.

User Journey

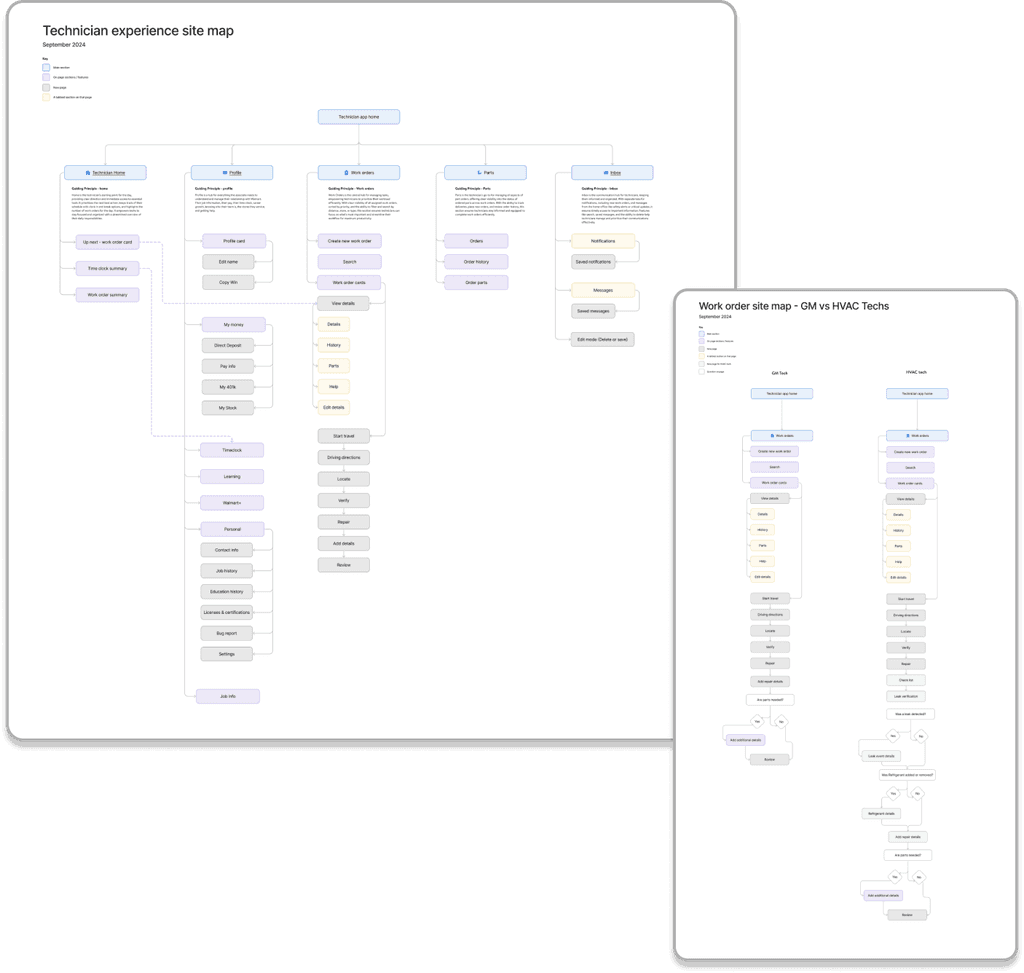

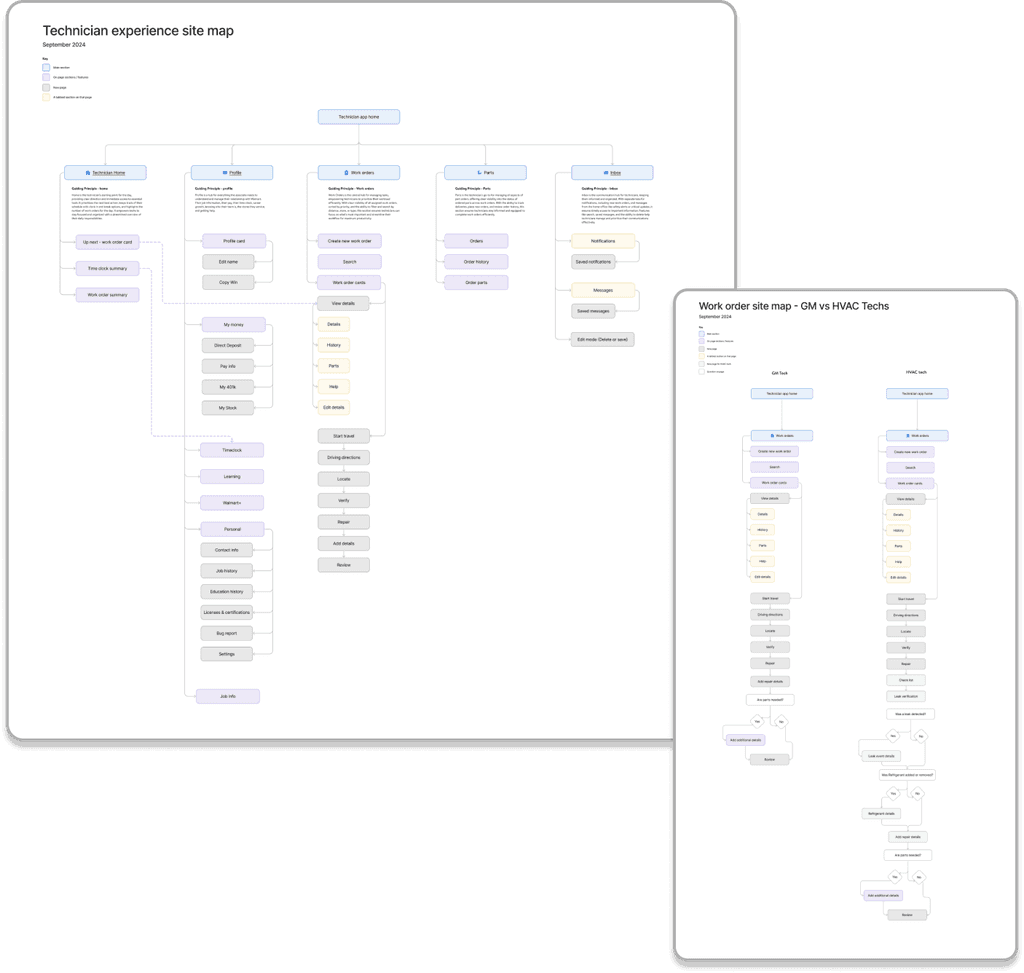

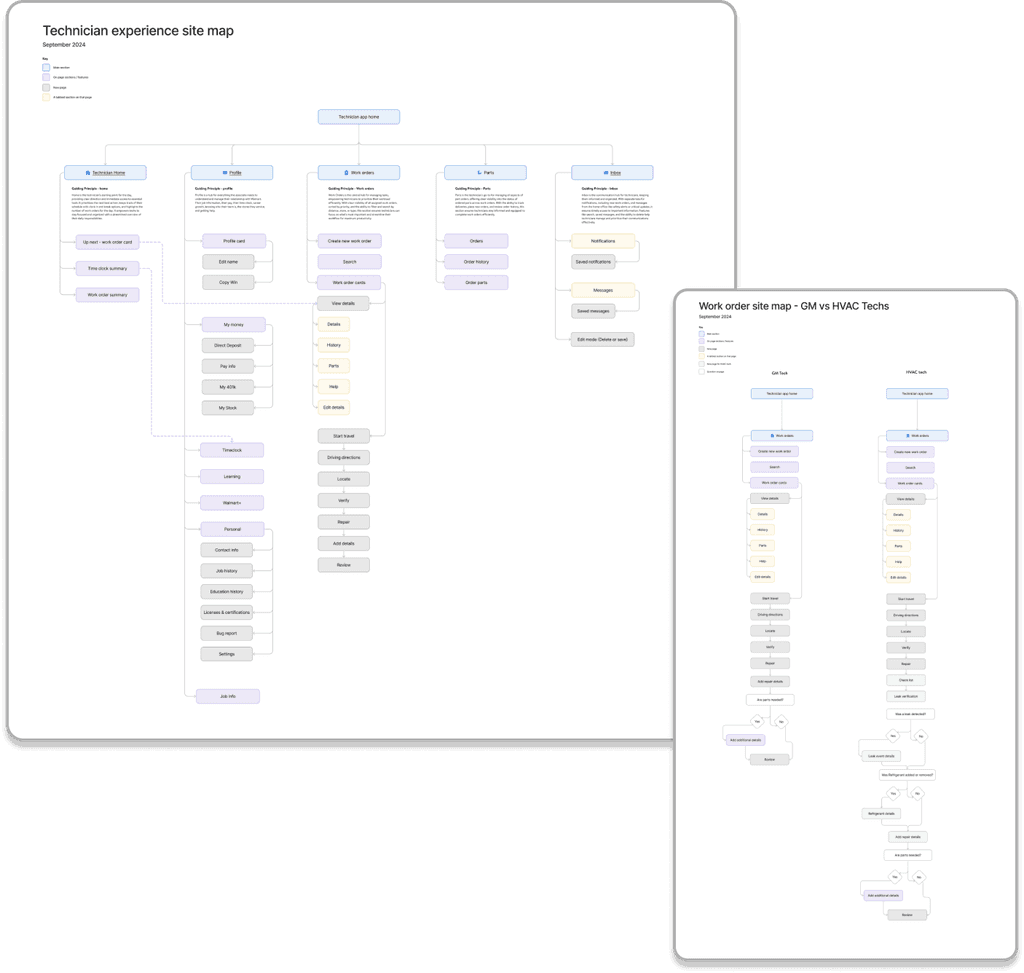

Information architecture

Creating a site map was crucial in establishing a clear structure for the new app. It helped us visualize the overall flow, define content organization, and identify key interactions for technicians. By mapping out the app's architecture, we ensured a logical and intuitive navigation system, which reduced complexity and minimized the learning curve for users. The site map also served as a valuable communication tool, aligning stakeholders on the app’s structure and guiding feature prioritization throughout the design process.

Site map

Site map

Site map

Information architecture

Creating a site map was crucial in establishing a clear structure for the new app. It helped us visualize the overall flow, define content organization, and identify key interactions for technicians. By mapping out the app's architecture, we ensured a logical and intuitive navigation system, which reduced complexity and minimized the learning curve for users. The site map also served as a valuable communication tool, aligning stakeholders on the app’s structure and guiding feature prioritization throughout the design process.

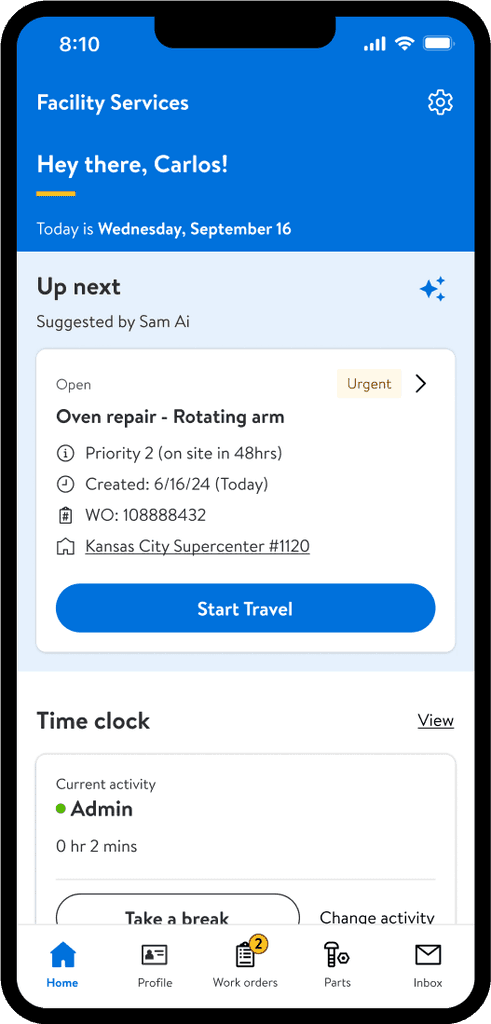

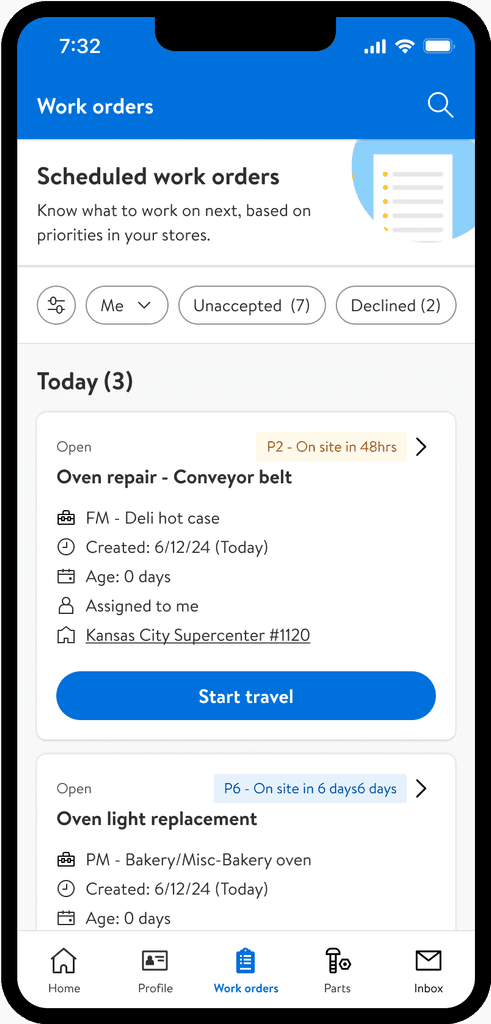

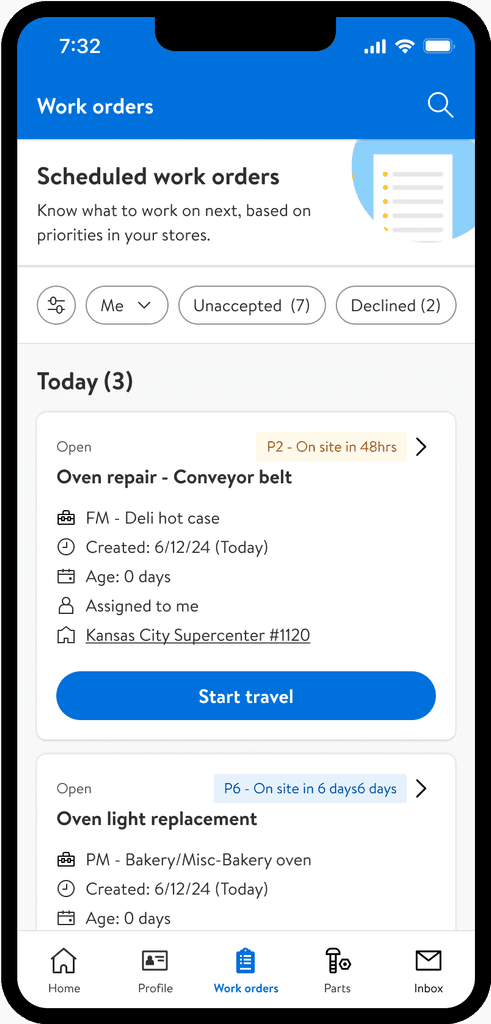

Gen Ai

Gen Ai

Problem area: High cost of outsourcing

Walmart incurs a high cost of outsourcing when technicians are routed inefficiently, or when they focus on the wrong thing.

Solution

We are incorporating machine learning and generative AI. This way we can automate the sorting of work orders for technicians so that we always lead them to their next best action. The system will consider the priority, technicians current location and time it takes to complete each work order.

User research

User research

Moderated user tests

Moderated user tests

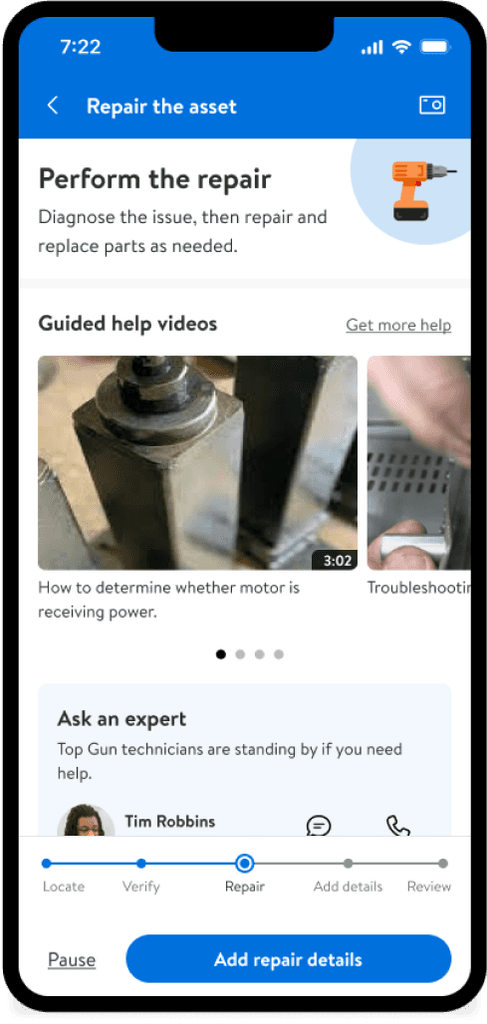

It was crucial for us to get the repair flow correct since it’s the most frequent task technicians perform, and any confusion or inefficiency could significantly impact their productivity and overall experience.

Distinct perspectives

Distinct perspectives

6 Experienced technicians

2 New to the job - less experienced technicians

6 Experienced technicians

2 New to the job - less experienced technicians.

User research

Insights & findings

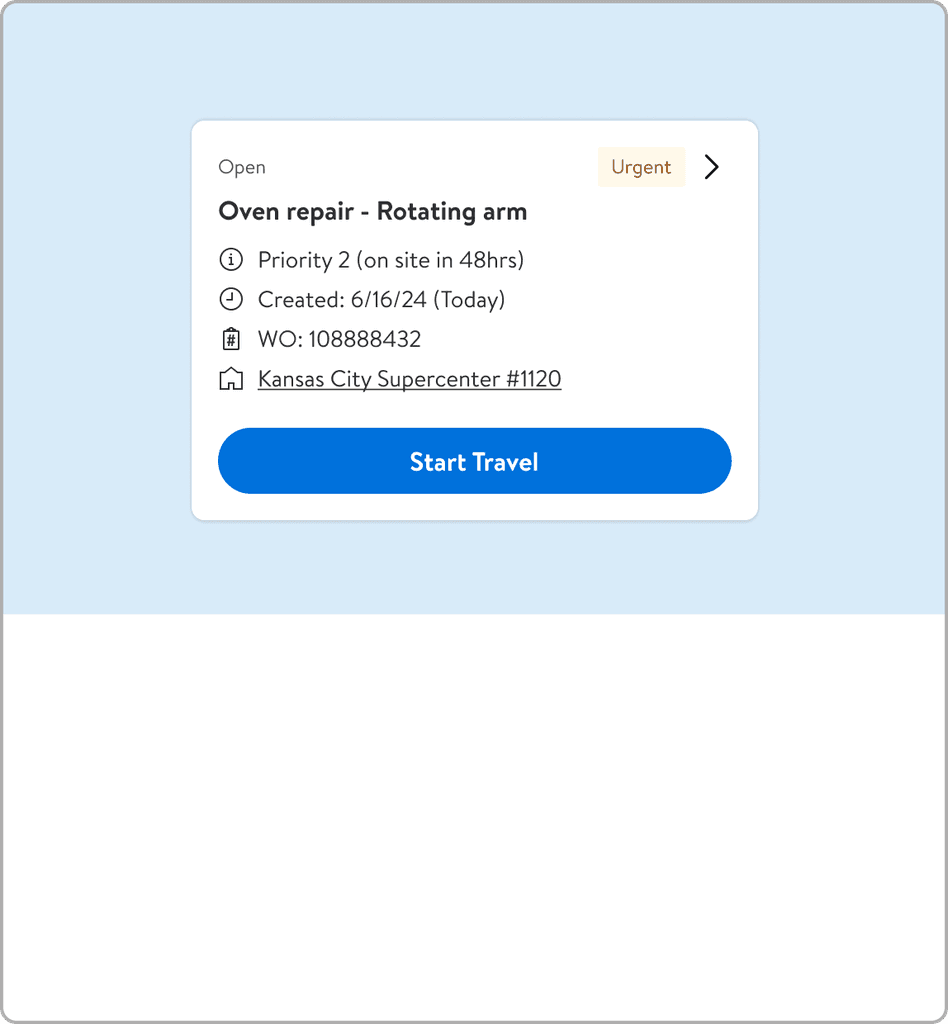

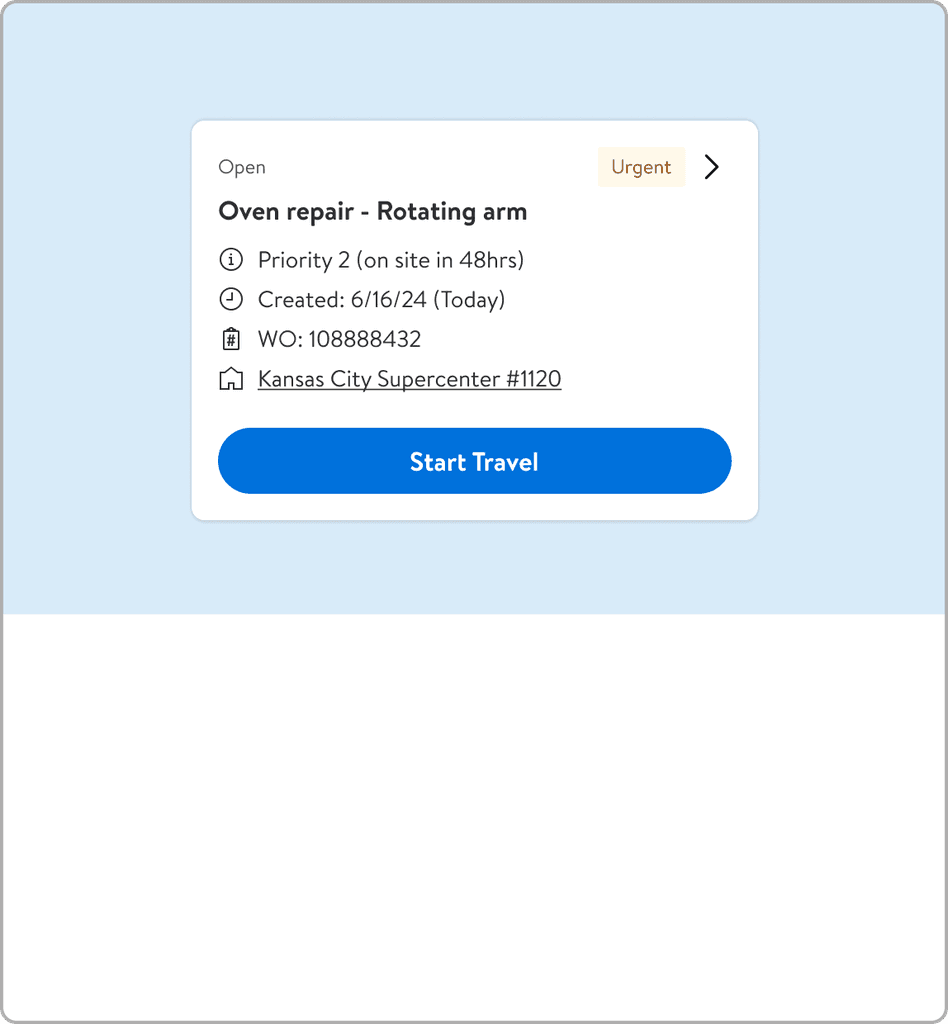

Streamline the details

Streamline the details

Focus on the key information by showing only the top 4 data points on work order cards. Technicians prioritize knowing the type of repair and its location, preferring to dive into the finer details once they’re on-site.

Focus on the key information by showing only the top 4 data points on work order cards. Technicians prioritize knowing the type of repair and its location, preferring to dive into the finer details once they’re on-site.

Streamline the details

Focus on the key information by showing only the top 4 data points on work order cards. Technicians prioritize knowing the type of repair and its location, preferring to dive into the finer details once they’re on-site.

Streamline the details

Focus on the key information by showing only the top 4 data points on work order cards. Technicians prioritize knowing the type of repair and its location, preferring to dive into the finer details once they’re on-site.

Streamline the details

Focus on the key information by showing only the top 4 data points on work order cards. Technicians prioritize knowing the type of repair and its location, preferring to dive into the finer details once they’re on-site.

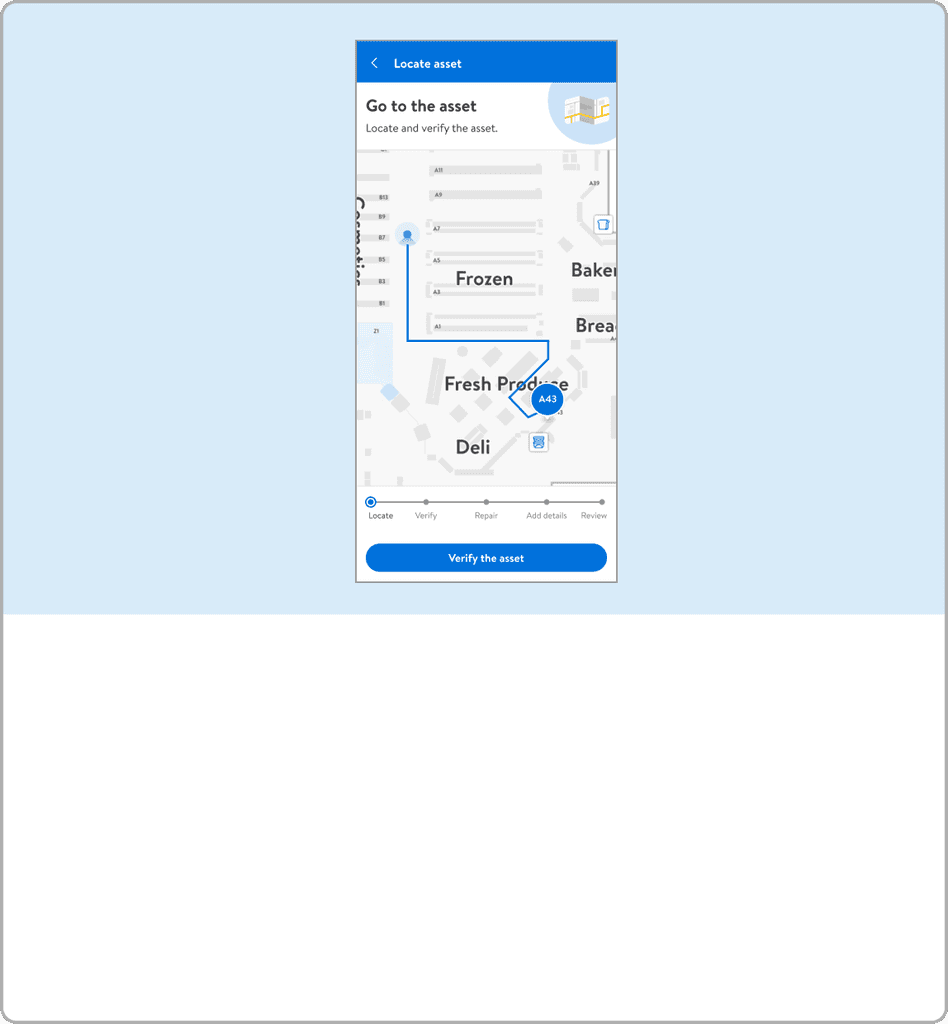

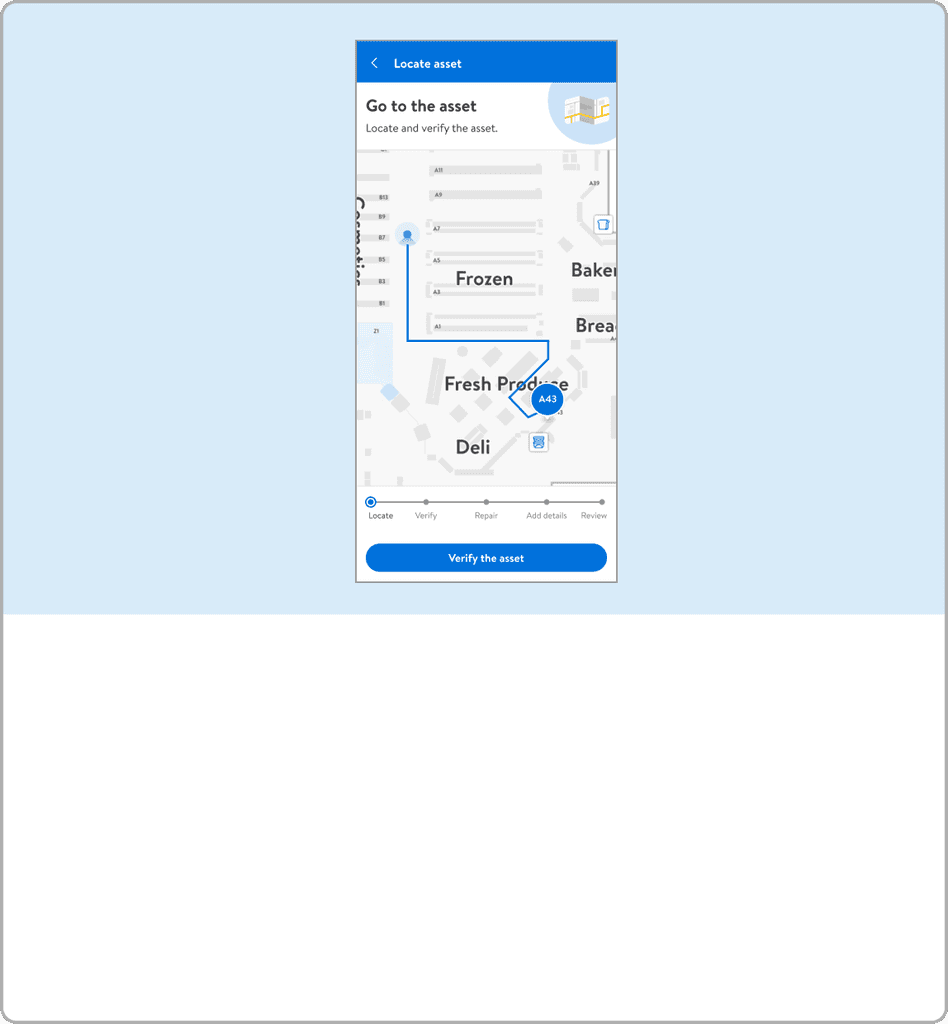

Reduce time locating assets

Reduce time locating assets

Technicians frequently lose valuable time searching for the asset needing repair when they arrive at a store. User testing indicated a strong preference for a map feature, so we incorporated the “item location” functionality from our associate experience team into the MVP.

Technicians frequently lose valuable time searching for the asset needing repair when they arrive at a store. User testing indicated a strong preference for a map feature, so we incorporated the “item location” functionality from our associate experience team into the MVP.

Reduce time locating assets

Technicians frequently lose valuable time searching for the asset needing repair when they arrive at a store. User testing indicated a strong preference for a map feature, so we incorporated the “item location” functionality from our associate experience team into the MVP.

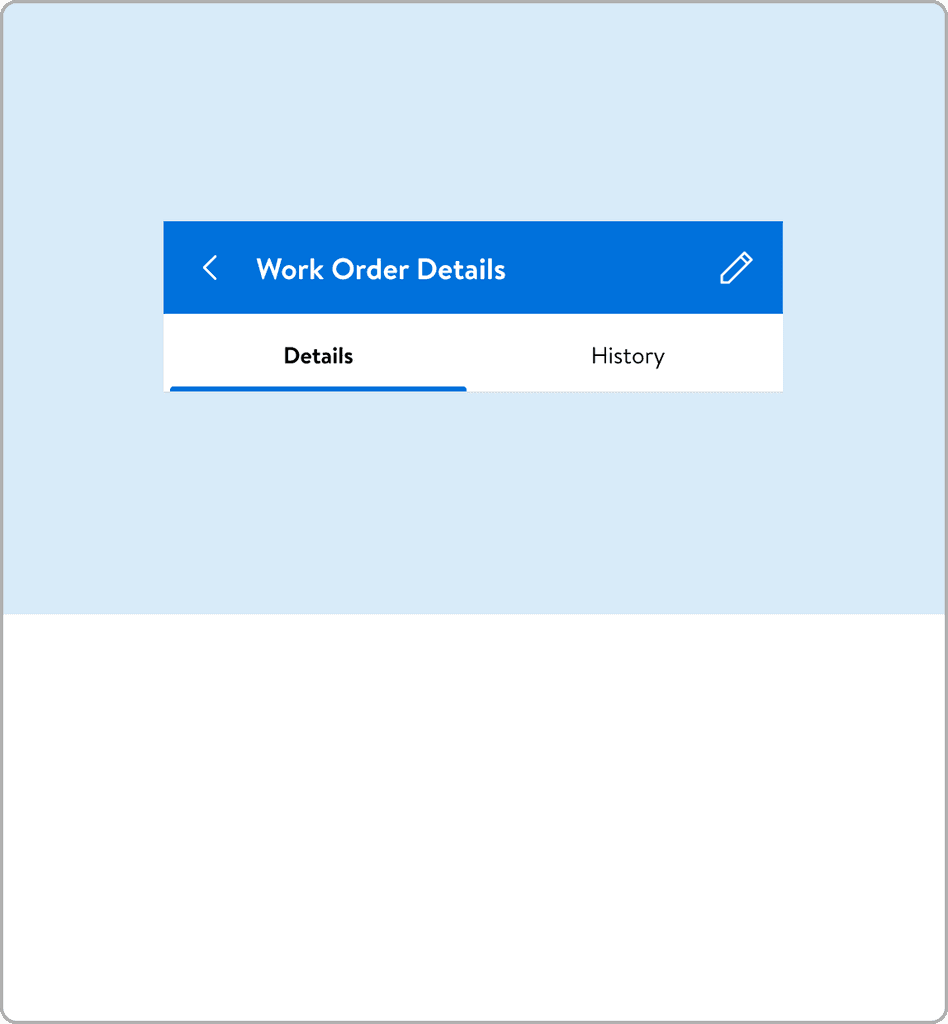

Include a history section

Include a history section

Technicians wanted visibility into the work order’s history—seeing if it was started by another technician, reassigned, or if parts had been ordered—all critical details to understand the status and context of the task.

Technicians wanted visibility into the work order’s history—seeing if it was started by another technician, reassigned, or if parts had been ordered—all critical details to understand the status and context of the task.

Include a history section

Technicians wanted visibility into the work order’s history—seeing if it was started by another technician, reassigned, or if parts had been ordered—all critical details to understand the status and context of the task.

Include a history section

Technicians wanted visibility into the work order’s history—seeing if it was started by another technician, reassigned, or if parts had been ordered—all critical details to understand the status and context of the task.

Include a history section

Technicians wanted visibility into the work order’s history—seeing if it was started by another technician, reassigned, or if parts had been ordered—all critical details to understand the status and context of the task.

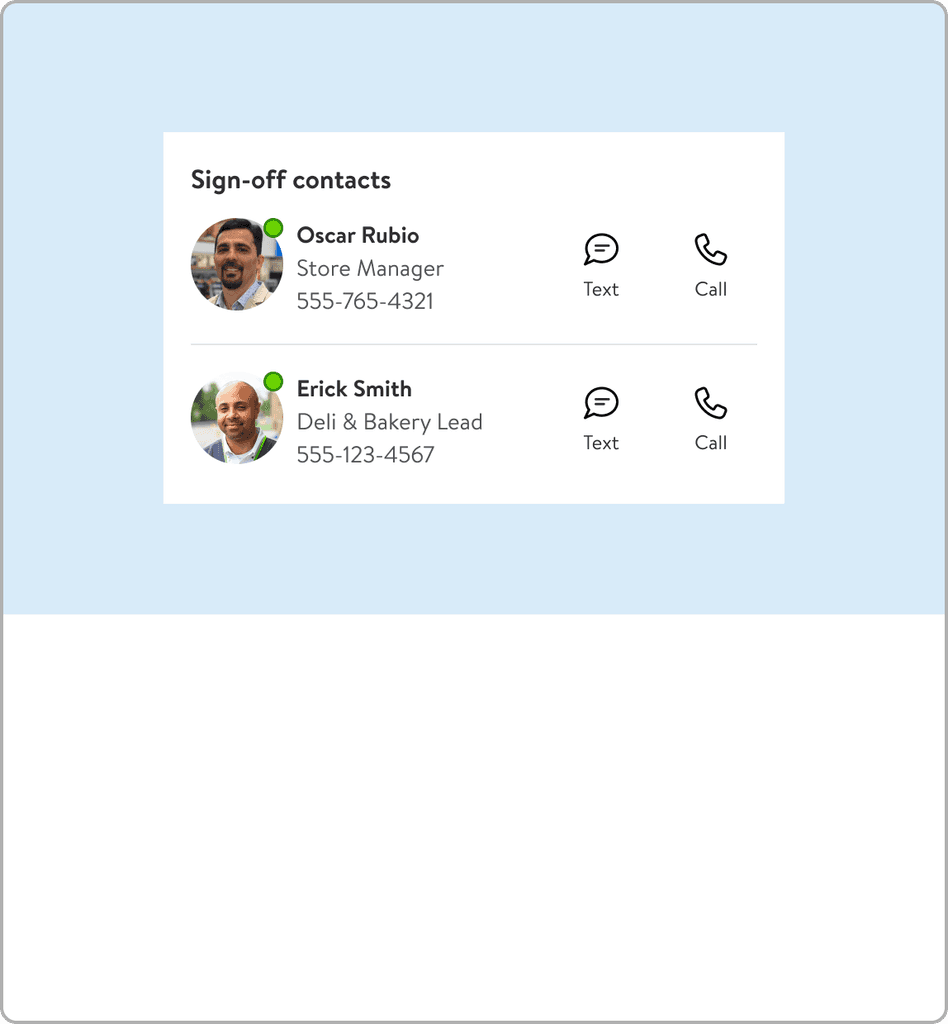

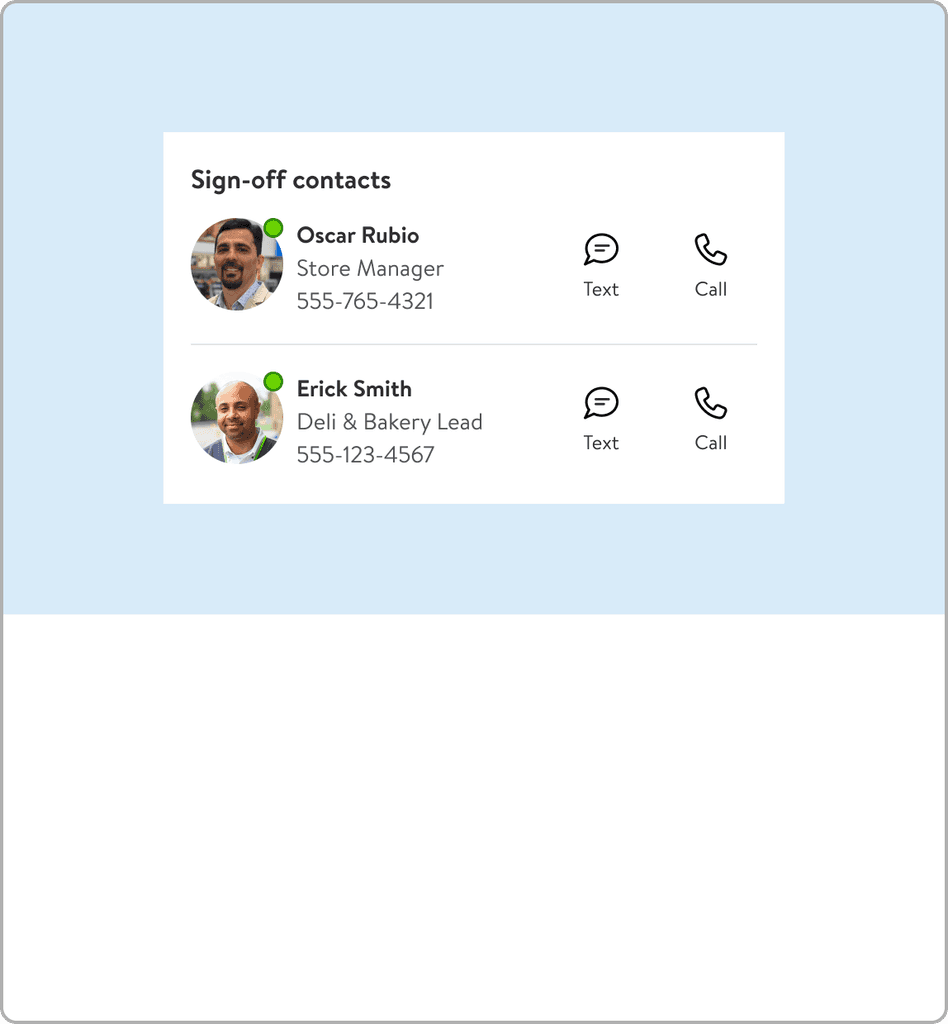

Quick Access to Sign-Off Contacts

Quick Access to Sign-Off Contacts

Technicians need more than just a name for sign-off; they wanted a quick and easy way to reach their contact, whether through a text or a call. Including a photo of the contact also helps technicians identify the right person when arriving at the store.

Technicians need more than just a name for sign-off; they wanted a quick and easy way to reach their contact, whether through a text or a call. Including a photo of the contact also helps technicians identify the right person when arriving at the store.

Quick Access to Sign-Off Contacts

Technicians need more than just a name for sign-off; they wanted a quick and easy way to reach their contact, whether through a text or a call. Including a photo of the contact also helps technicians identify the right person when arriving at the store.

Insights & findings

MVP

MVP

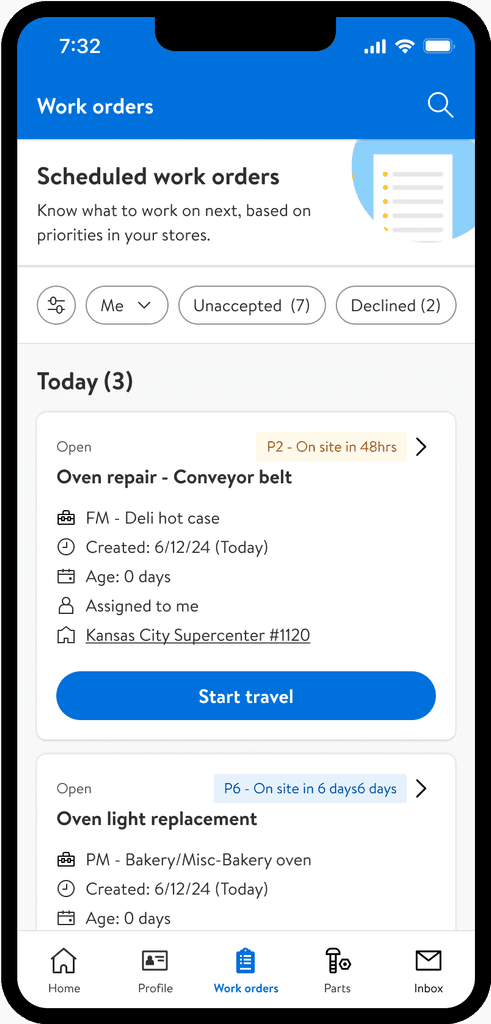

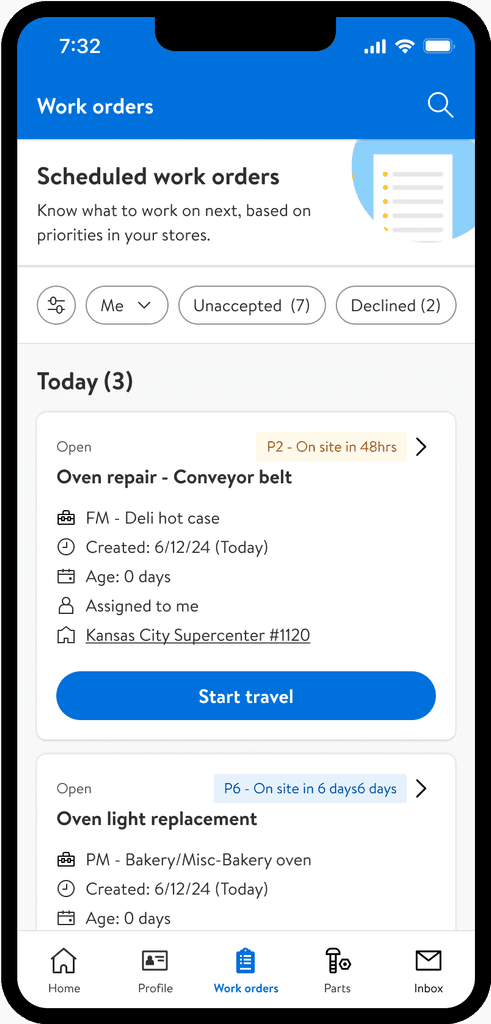

Key screens

We designed over 250 key screens as part of the Minimum Viable Product (MVP) to ensure that every aspect of the technician workflow was thoughtfully addressed. From task prioritization and work order management to parts ordering and reporting, the extensive design work laid the foundation for a robust and comprehensive app experience.

Key screens

We designed over 250 key screens as part of the Minimum Viable Product (MVP) to ensure that every aspect of the technician workflow was thoughtfully addressed. From task prioritization and work order management to parts ordering and reporting, the extensive design work laid the foundation for a robust and comprehensive app experience.

MVP

Final Designs

Final Designs

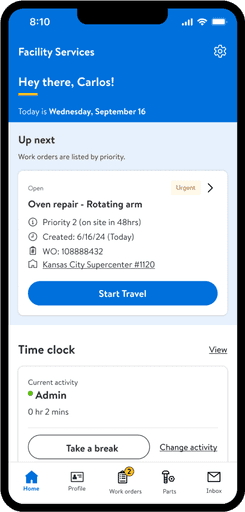

A technician is guided to their next best action, but can also easily see work orders for the day, week etc.

A technician is guided to their next best action, but can also easily see work orders for the day, week etc.

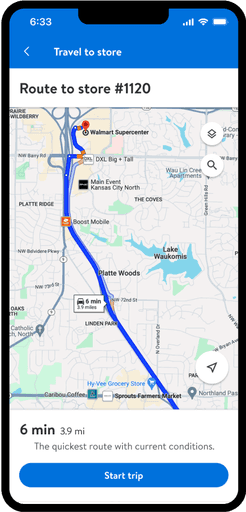

The technician can opt for a guided route via Google maps integrated into the app.

The technician can opt for a guided route via Google maps integrated into the app.

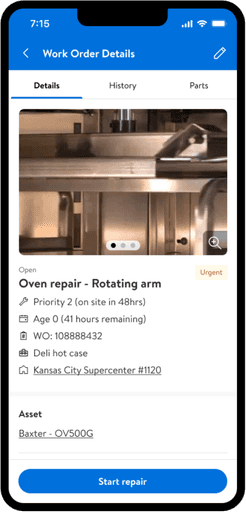

The Once they arrive at the store, the technician can view the work order details, before we guide them with in store maps to the asset.

The Once they arrive at the store, the technician can view the work order details, before we guide them with in store maps to the asset.

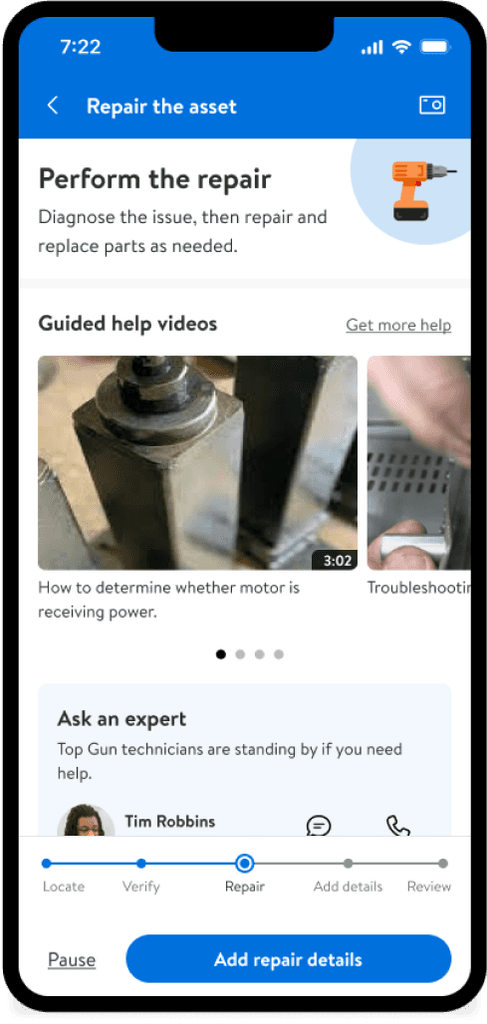

The technician also has relevant asset help content specific to the repair at their fingertips.

The technician also has relevant asset help content specific to the repair at their fingertips.

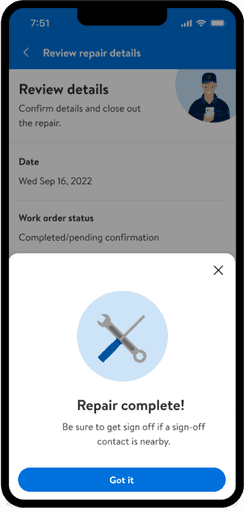

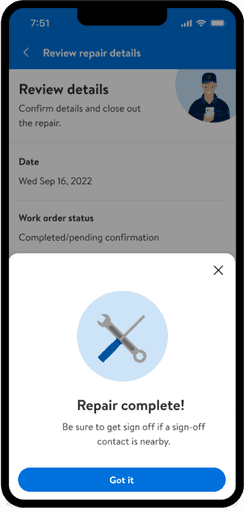

Once the repair is completed they review the details they added and move to their next task

Once the repair is completed they review the details they added and move to their next task

The technician also has relevant asset help content specific to the repair at their fingertips.

Once the repair is completed they review the details they added and move to their next task

How are we measuring success?

How are we measuring success?

Reducing windshield time & turnover

Reducing windshield time & turnover

The main KPIs for this app are reducing windshield time—measuring how efficiently technicians respond to and complete work orders—and a decrease in technician turnover, which currently sits at 70%.

The main KPIs for this app are reducing windshield time—measuring how efficiently technicians respond to and complete work orders—and a decrease in technician turnover, which currently sits at 70%.

Reducing windshield time & turnover

The main KPIs for this app are reducing windshield time—measuring how efficiently technicians respond to and complete work orders—and a decrease in technician turnover, which currently sits at 70%.

How are we measuring success?

What's next?

What's next?

Expanding to chain

The new app will be piloted in 60 regions and plans to expand to all by late 2025.

Add more functionality

We plan to add additional help content for performing repairs, increase personalization, and include parts ordering within the app—a feature that had to be cut due to timeline constraints and engineering resources.

What's next?

Expanding to chain

The new app will be piloted in 60 regions and plans to expand to all by late 2025.

Add more functionality

We plan to add additional help content for performing repairs, increase personalization, and include parts ordering within the app—a feature that had to be cut due to timeline constraints and engineering resources.

Gen Ai

Problem area: High cost of outsourcing

Walmart incurs a high cost of outsourcing when Technicians are routed inefficiently, or when they focus on the wrong thing.

Solution

We are incorporating machine learning and generative AI. This way we can automate the sorting of work orders for technicians so that we always lead them to their next best action. The system will consider the priority, technicians current location and time it takes to complete each work order.